HPO Piston Seals

NAK is committed to providing the highest quality with great product performance. We produce the seals that are suited to meet the customer requirements of quality and performance. The perfect quality assurance system, SCADA, and various inspection equipment help us to monitor the whole production process, assure stability of this process and HPO Piston Seals quality.

HPO Piston Seals

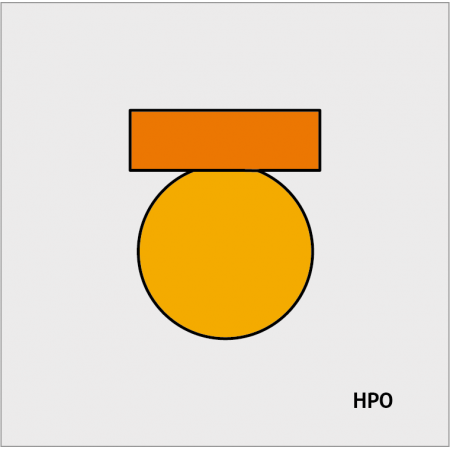

Model - HPO

Product Description

The HPO Piston Seals are a combination seal made of a PTFE profile ring and an O-Ring energizer. The PTFE seal has low friction characteristics which make it perfect for reducing energy loss and increasing the service life of the mechanism. Since the PTFE profile ring has a wide operating temperature range, the seal’s operating temperature range can be suitably adjusted by choosing an optimum O-Ring material. Thus providing a wide temperature range for the Seal. While similar to an HOD Piston Seal, the HPO Piston Seal can save installation space, while still being able to maintain a tight seal for a high-speed, high pressure, double acting environment.

Material

O-Ring -NBR

Friction Ring -PTFE

Product Advantages

Application

Agricultural equipment, injection molding machines, fork-lifts and loading platforms

Operating Conditions

Gap Dimension

Surface Roughness

The HPO Piston Seals are a combination seal made of a PTFE profile ring and an O-Ring energizer. The PTFE seal has low friction characteristics which make it perfect for reducing energy loss and increasing the service life of the mechanism. Since the PTFE profile ring has a wide operating temperature range, the seal’s operating temperature range can be suitably adjusted by choosing an optimum O-Ring material. Thus providing a wide temperature range for the Seal. While similar to an HOD Piston Seal, the HPO Piston Seal can save installation space, while still being able to maintain a tight seal for a high-speed, high pressure, double acting environment.

Material

O-Ring -NBR

Friction Ring -PTFE

Product Advantages

- Good media resistance

- Low frictional resistance

- Wide operating temperature range depending on the O-Ring material

- Very good static and dynamic tightness

- High-speed sliding

- Fit small grooves heights

Application

Agricultural equipment, injection molding machines, fork-lifts and loading platforms

Operating Conditions

| Media | Mineral oils |

| Pressure | ≦35 Mpa |

| Speed | ≦1.5 m/s |

| Temperature Range | -40°C , +100°C |

Gap Dimension

| 200 Bar | 250 Bar | 350 Bar |

| 0.6 mm | 0.42 mm | 0.25 mm |

Surface Roughness

| Sliding Surface | Groove Base | Groove Flanks | |

| Ra | 0.1~0.8 µm | ≦1.6 µm | ≦3.2 µm |

| Rz | 0.4~3.2 µm | ≦6.3 µm | ≦12.5 µm |

We are interested in helping you decide which

HPO Piston Seals

work best for your application. contact us if you need product, technical or application advice or want to collaborate with a NAK technical specialist.Enquiry Now

Products List

NAK Sealing Technologies Corporation

To find and shop the best HPO Piston Seals, you need to know about the highest quality of HPO Piston Seals manufacturer, supplier, wholesaler, distributor, OEM and ODM from a factory

UOP

none

999999999

http://schema.org/InStock

USD

2020-12-31

https://www.oilsealssupplier.com/uop-piston-seals.html

NAK Sealing Technologies Corporation

90out of

100based on

100user ratings

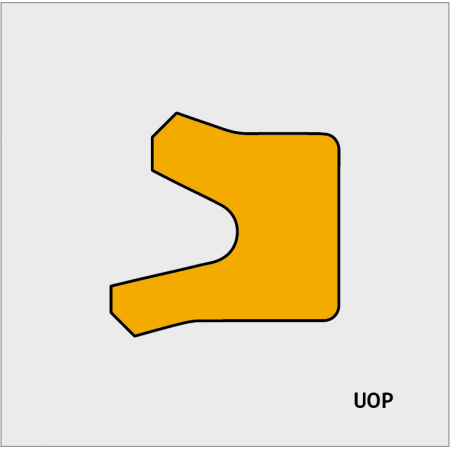

Product Description

The UOP Piston Seal is a single acting, U-cup piston seal with an asymmetrical design. The seal can be in a double-acting cylinder by using two seals in a back-to-back arrangement. The outer diameter of the seal has a shortened lip which increases the cross-sectional area. This seal is both an excellent dynamic as well as static seal. It can withstand pressures of up to 40Mpa considering a smaller extrusion gap. The UOP Piston Seal is mostly used in construction and earth-moving machinery.

Material

Polyurethane

Product Advantages

Good media resistance

Excellent wear resistance

Wide operating temperature range

Very good static and dynamic tightness

Application

Earth-moving machinery, construction machinery, agricultural equipment, injection molding machines, fork-lifts, loading platforms and standard cylinders.

Operating Conditions

Media

Mineral oils

Pressure

≦40 Mpa

Speed

≦0.5 m/s

Temperature Range

-40°C , +100°C

Gap Dimension

140 Bar

210 Bar

350 Bar

0.25 mm

0.15 mm

0.08 mm

Surface Roughness

Sliding Surface

Groove Base

Groove Flanks

Ra

0.1~0.8 µm

≦0.8 µm

≦3.2 µm

Rz

0.4~3.2 µm

≦3.2 µm

≦12.5 µm

NAK Sealing Technologies Corporation

To find and shop the best HPO Piston Seals, you need to know about the highest quality of HPO Piston Seals manufacturer, supplier, wholesaler, distributor, OEM and ODM from a factory

COP

none

999999999

http://schema.org/InStock

USD

2020-12-31

https://www.oilsealssupplier.com/cop-piston-seals.html

NAK Sealing Technologies Corporation

90out of

100based on

100user ratings

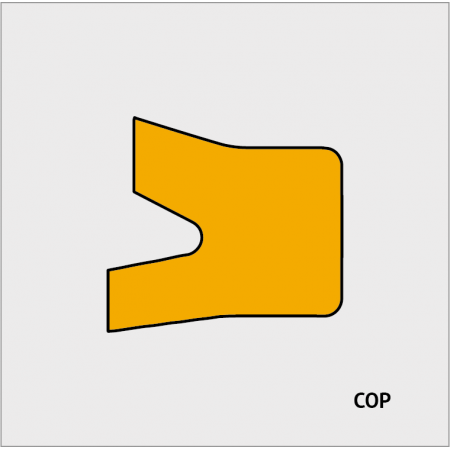

Product Description

The COP Piston Seal is a single acting U-cup seal. Its inner diameter is designed to create a tight seal, while its shortened outer diameter is designed to reduce friction. The cross-section due to the shortened lip is smaller, but it still provides very strong sealing. The COP Piston Seal can withstand maximum pressures of up to 30Mpa. This kind of seal is perfect for forklifts, mold injection machines, agricultural equipment etc.

Material

Polyurethane

Product Advantages

Good media resistance

Excellent wear resistance

Wide operating temperature range

Very good static and dynamic tightness

Easier installation.

Application

Earth-moving machinery, injection molding machines and forklifts

Operating Conditions

Media

Mineral oils

Pressure

≦30 Mpa

Speed

≦0.5 m/s

Temperature Range

-40°C , +100°C

Gap Dimension

140 Bar

210 Bar

350 Bar

0.25 mm

0.15 mm

0.08 mm

Surface Roughness

Sliding Surface

Groove Base

Groove Flanks

Ra

0.1~0.8 µm

≦0.8 µm

≦3.2 µm

Rz

0.4~3.2 µm

≦3.2 µm

≦12.5 µm

NAK Sealing Technologies Corporation

To find and shop the best HPO Piston Seals, you need to know about the highest quality of HPO Piston Seals manufacturer, supplier, wholesaler, distributor, OEM and ODM from a factory

HOD

none

999999999

http://schema.org/InStock

USD

2020-12-31

https://www.oilsealssupplier.com/hod-piston-seals.html

NAK Sealing Technologies Corporation

90out of

100based on

100user ratings

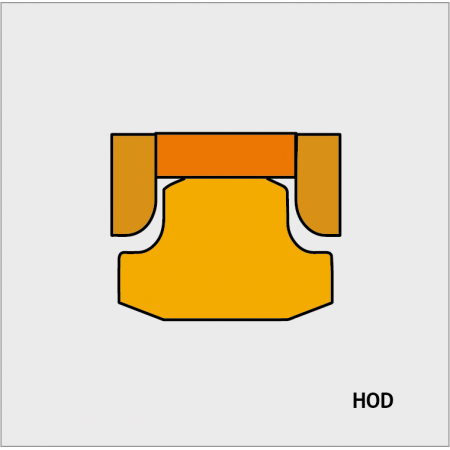

Product Description

The HOD Piston Seal is a four-piece combination seal used in heavy-duty hydraulic cylinders. The primary PTFE seal is made of low-friction materials which is perfect for the high-speed and high pressure hydraulic cylinder application. The HOD Piston Seal is a double acting seal and is supported by nylon back-up rings on either side to allow sealing and protect the main PTFE profile from high pressures on both sides of the piston. Together, this combination seal can withstand pressures of up to 50Mpa. The HOD Piston Seal is mostly used in mining equipment, construction machinery and high-speed hydraulic cylinders.

Material

NBR

Nylon

Friction Ring -PTFE

Product Advantages

Excellent media resistance in case of suitable compound selection

Excellent gap extrusion resistance

Very good dynamic tightness even with pressure peaks

High-speed sliding

Application

Mining equipment, Earth-moving machinery and construction machinery

Operating Conditions

Media

Mineral oils

Pressure

≦50 Mpa

Speed

≦1.5 m/s

Temperature Range

-40°C , +100°C

Gap Dimension

510 Bar

650 Bar

800 Bar

1 mm

0.45 mm

0.19 mm

Surface Roughness

Sliding Surface

Groove Base

Groove Flanks

Ra

0.1~0.8 µm

≦1.6 µm

≦3.2 µm

Rz

0.4~3.2 µm

≦6.3 µm

≦12.5 µm

NAK Sealing Technologies Corporation

To find and shop the best HPO Piston Seals, you need to know about the highest quality of HPO Piston Seals manufacturer, supplier, wholesaler, distributor, OEM and ODM from a factory

HPS

none

999999999

http://schema.org/InStock

USD

2020-12-31

https://www.oilsealssupplier.com/hps-piston-seals.html

NAK Sealing Technologies Corporation

90out of

100based on

100user ratings

Product Description

The HPS Piston Seal is a PTFE seal combined with a square seals energizers. The low-friction characteristics of PTFE combined with the performance abilities of the square seals make it able to provide a strong and efficient seal. The square seals design provides a robust sealing as it is less likely to slide or roll in the groove under the high speed and pressure of a double acting cylinder.

Material

Square Ring-NBR

Friction Ring -PTFE

Product Advantages

Good media resistance

Low frictional resistance

Wide operating temperature range depending on the Square Ring material

Very good static and dynamic tightness

High-speed sliding

Fit small grooves heights

Application

Agricultural equipment, injection molding machines, fork-lifts and loading platforms

Operating Conditions

Media

Mineral oils

Pressure

≦35 Mpa

Speed

≦1.5 m/s

Temperature Range

-40°C , +100°C

Gap Dimension

140 Bar

210 Bar

350 Bar

0.6 mm

0.6 mm

0.23 mm

Surface Roughness

Sliding Surface

Groove Base

Groove Flanks

Ra

0.1~0.8 µm

≦1.6 µm

≦3.2 µm

Rz

0.4~3.2 µm

≦6.3 µm

≦12.5 µm

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlands

Nederlands العربية

العربية Tiếng Việt

Tiếng Việt ไทย

ไทย Indonesia

Indonesia 日本語

日本語 Türkçe

Türkçe 简体中文

简体中文